Grate Cleat is an Australian company that has developed a clip-on nylon Grate Cleat specifically for open metal grating to reduce pedestrian slips on metal grating stairs and walkways that are used extensively in industry.

This metal grating has been around for over 50 years and is still the product to use for stairs and walkways as it has been the only choice when light, air and liquids need to pass through it.

But when it is wet or worn those areas can be notoriously slippery for personnel. This can be expensive to fix.

Some of the methods tried to fix the issue have been cutting grooves into the load bar with a grinder or welding small lumps of weld onto the load bars, which is high-risk work that in the end ruins the grating due to rusting or warping.

The other common method involves drilling and bolting anti-slip plates onto the slippery areas, which is labour intensive and can create a surface for product to build up on instead of falling through as intended.

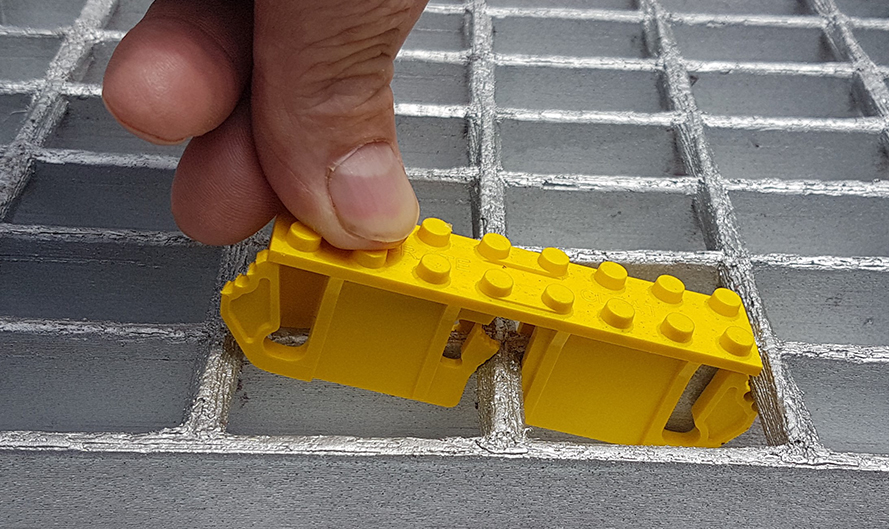

To address this, the International Patent Pending Grate Cleat can be installed, clipping in place in seconds with no tools required, adding a double row extra traction only to areas that need it.

It eliminates the cost of replacing or repairing worn metal grating and greatly reduces the ‘slippery when wet’ issue in others, while still allowing light, air and products to pass through it as intended.

Simply clipping on traction to areas only when and where they are needed is a big saving.

Grate Cleats unique way of locating means that the Grate Cleat doesn’t need to protrude below the load bars to lock on so does not interfere with the support steel holding the grating up.

This also means that only one size of Grate Cleat is required for different depths of load bar the standard of which has a depth of 25mm and 32mm.

Allowing for uniform patterns that can be placed as densely or sparsely as an area requires.

Annually slips, trips and falls make up a significant portion of recorded accidents. The most common injuries are musculoskeletal, dislocations, fractures, or cuts and bruises.

Based on Work Safe research, this figure was 23 per cent in 2015-16, which is nearly a quarter of all reported accidents.

Having just one worker off for a week can cost a company thousands of dollars.

That money could be better spent reducing the chance of a slip in the first place now that there’s a simple solution available.

Grate Cleat is made from a UV stabilised polymer that is coloured bright yellow to stand out well in low light conditions.

This makes stair edges and platforms or areas that you need to take care on very noticeable. The polymer is wear-resistant and flame retardant (UL94-V0).

It’s very strong and capable of withstanding a wide range of acids and alkaline, oils and petrol without corrosion or effect. The arms that hold the Grate Cleat in place help to reduce sideways movement on the load bars making them feel safe to walk on. With the Grate Cleats being made from polymer the colour won’t flake off, it won’t rust or rattle and is electrically isolative.

The metal grating used for personnel stairs and walkways are normally made from 25mm or 32mm deep bars that are 5mm thick.

The imperial equivalent size is 1” or 1-1/4” deep bars that are 3/16” thick. The twist bar centres are spaced at either 50mm or 100mm. The imperial equivalent twist bar spacing is 2” and 4”.

Grate Cleats fit this range of grating sizes, including the imperial equivalents and various grating manufacturers’ products with just one product.

Using only one product makes it simple to order or stock and easy for installation.

This really is an innovative and cost-effective product in the effort to reduce slips in industries that use this type of grating.

More information available on Grate Cleats’ website here.