Chevron Australia and Aker Solutions have made an order worth approximately $120 million for ABB to supply the overall Electrical Power System (EPS) for the Jansz-Io Compression (J-IC) project.

The Jansz-Io field, located around 200 kilometres offshore of the north-western coast of Australia, has been supplying gas to the Chevron-operated Gorgon gas processing facilities on Barrow Island since 2015.

After approximately 10 years of production, the reservoir pressure at Jansz-Io will decline, requiring modification of the existing subsea gas gathering network to maintain long-term natural gas supply.

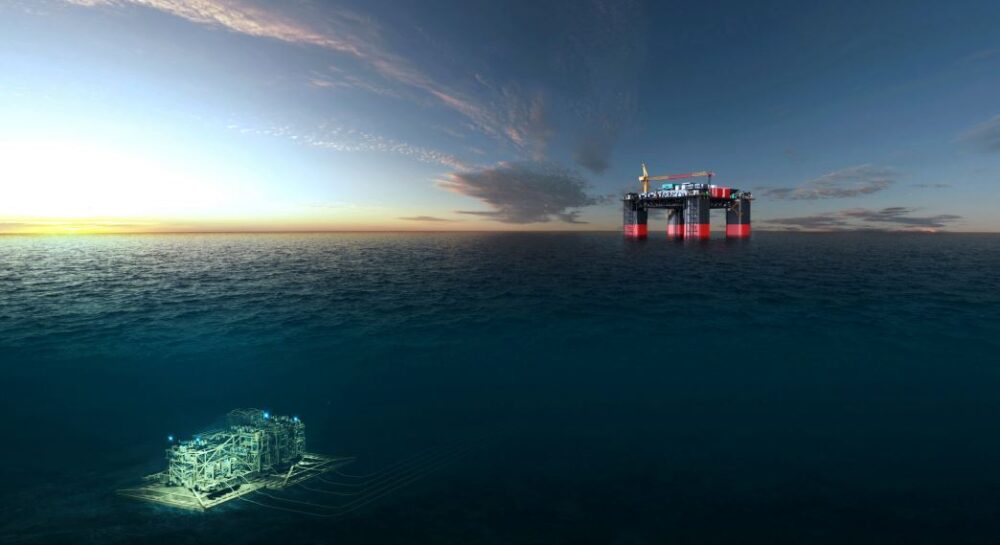

The J-IC project will use subsea compression technology to enhance the recoverability of the Jansz-Io field and maintain the supply of natural gas to the facilities on Barrow Island.

The project marks only the third time that world-leading subsea compression technology is being deployed globally and the first time outside of Norway [1] where ABB is also responsible for providing the EPS.

The project will involve the construction and installation of a 27,000-tonne (Topside and Hull) normally unattended floating Field Control Station (FCS), approximately 6,500 tonnes of subsea compression infrastructure and a 135-kilometre submarine power cable linked to Barrow Island.

“The Jansz-Io Compression project is a major enabler in maintaining an important source of natural gas to customers in Asia Pacific. It will support energy transition across the region where many countries primarily rely on coal for energy generation,” said Peter Terwiesch, President, Process Automation at ABB.

“Burning natural gas produces around half as much carbon dioxide per unit of energy compared with coal. We’re proud to be leading the way in the global energy industry by pioneering innovative subsea power technologies that bring us closer to a carbon-neutral future. This project reflects our close collaboration and trusted subsea history with Chevron and Aker Solutions.”

Brandon Spencer, President, Energy Industries at ABB, added that the technology significantly reduces power consumption and emissions compared to power generated offshore by local gas turbines and compressors located topside.

“Subsea compressors are key to helping improve reservoir recoverability and ensuring optimal use of resources from existing fields,” Mr Spencer said.

Maria Peralta, Subsea Executive Vice-President at Aker Solutions, added: “This is a very important project for us as it supports our commitment to enable lower-carbon oil and gas production and develop renewable solutions to meet future energy needs. We are pleased to once again be joining forces with ABB to take subsea solutions to the next level and accelerate the transition to sustainable energy production.”

ABB will provide the majority of the electrical equipment, both topside and subsea, for J-IC. The project will combine two core ABB technologies – power from shore and Variable Speed Drive (VSD) long step-out subsea power – for the first time. The electrical system will be able to transmit 100 megavolt-amperes over a distance of approximately 140 kilometres and at depths of 1,400 metres.

The contract was awarded following concept development and a front-end engineering and design (FEED) study. Work will start immediately and the subsea compression system is expected to be in operation in 2025.

The Chevron-operated Gorgon Project is a joint venture between the Australian subsidiaries of Chevron (47.333 per cent), ExxonMobil (25 per cent), Shell (25 per cent), Osaka Gas (1.25 per cent), Tokyo Gas (1 per cent) and JERA (0.417 per cent).

[1] The Åsgard and Gullfaks fields in Norway were the first to use subsea compression technology.