Global technology company Welltec has launched a new product that provides four different applications and is designed to bring greater reliability, flexibility and efficiency to the well construction process.

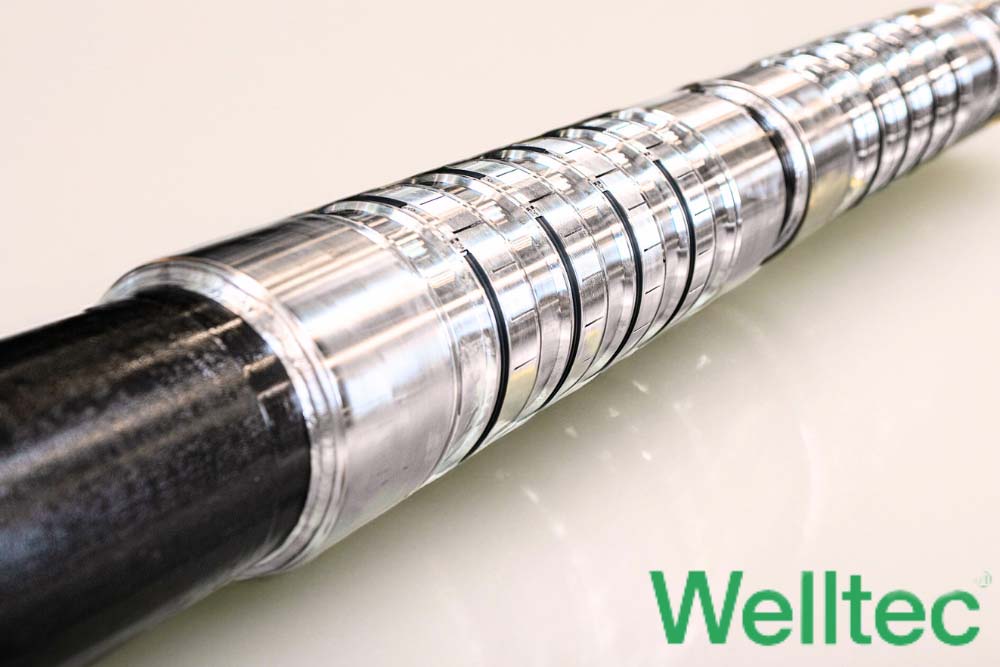

The Welltec Expandable Anchor (WEA) is an API-qualified anchoring in cased hole completion system that was developed on the field-proven platform of Welltec’s metal expandable packer technology.

Its four in one completion system means that it can be used as a liner hanger, tieback liner, inner-string packer and cased hole plug.

All versions of the product are qualified to the API 19LH V1 standard and are fully compatible with Welltec’s Metal Expandable Packer (MEP) portfolio.

The WEA solution is a machined sleeve which uses a surface-controlled hydraulic expansion process utilised within well construction and completion.

Welltec Global Solutions Director for Well Completions Paul Hazel said the technology has proven reliable for both installations and long-term solution capability.

“Many on-market solutions use a complex series of moving parts for setting and have multiple restrictions on well geometry to deliver reliable anchoring. This inevitably increases the risk of failure which can result in expensive remedial work or may result in the completion being pulled back to surface to be re-dressed and re-run. It is exactly this type of risk that we are eliminating with the WEA,” said Hazel.

Some of the the other benefits of the WEA includes:

- options for reciprocation, circulation, and rotation during deployment of the completion string

- a large running clearance — high circulation and low Equivalent Circulating Density (ECD)

- compatible with feedthrough lines

- eliminates the need for a deburr run when deployed within perforated liners and casings

- capable of bi-directional anchoring with proven MEP sealing to V0.

Welltec Vice President of Well Completions Wai Hoe Chum said: “Our Design & Engineering team has developed this solution with a commitment to three focus points: reliability, flexibility, and efficiency. Rigorous testing over a two-year period has led to the development of a single solution that provides operators with a clear path to securing well integrity in vastly different scenarios.”

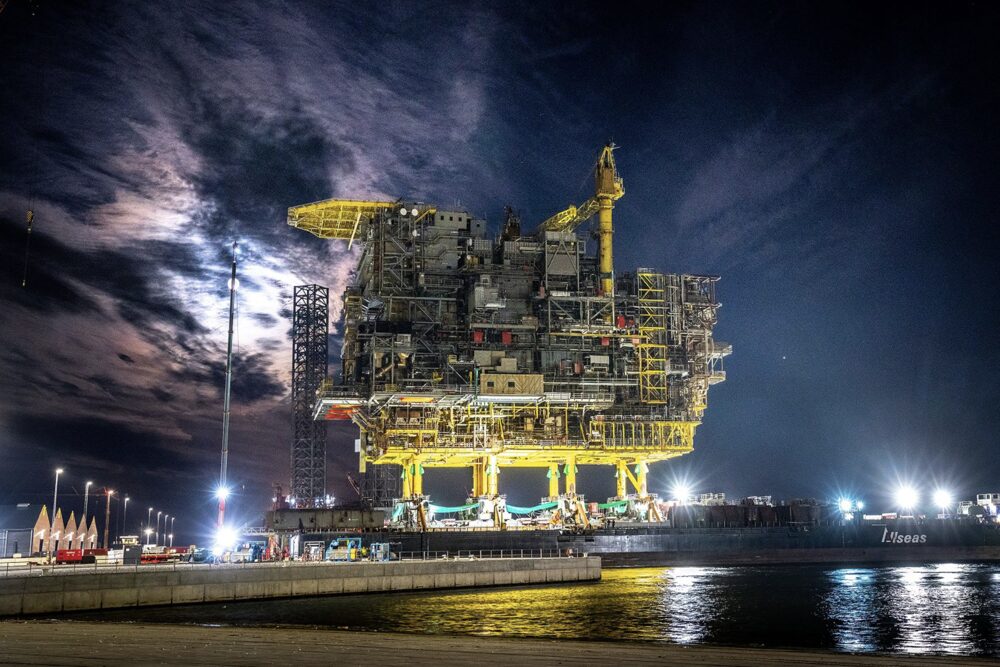

The new product has already been deployed onshore in America and offshore in the Middle East — with further deployments scheduled.